In the world of pharmaceuticals, maintaining the potency and efficacy of medications is not just a priority—it’s a necessity. Many medications, particularly vaccines, biologics, and recombinant products, require strict temperature controls to remain effective. The Cold Chain in Pharma ensures that these sensitive drugs are stored, transported, and delivered under optimal conditions, preserving their integrity from production to patient. As global warming heightens concerns over temperature stability, the importance of a robust cold chain system has never been greater. In this blog, we’ll explore the future of cold chain management in the pharmaceutical industry, the latest trends, and the cutting-edge technologies shaping this essential sector.

The Importance of Cold Chain in Pharmaceuticals

The significance of the cold chain in pharma is grounded in the science of maintaining a stable temperature environment for sensitive products. When we talk about pharmaceuticals like vaccines, insulin, and complex biologics, even slight deviations in temperature can lead to a reduction in efficacy or, in severe cases, a complete loss of potency. This could mean the difference between a life-saving medicine working as intended or failing to deliver its therapeutic effect.

With the rise in global temperatures, the Cold Chain in Pharma is facing unprecedented challenges. A single break in the chain—whether during storage, transportation, or delivery—can lead to compromised medication that could risk patient health. This makes a robust and reliable cold chain not only a logistical necessity but also a moral and ethical responsibility for pharmaceutical companies.

Why is Cold Chain Management Crucial?

1. Preserving Potency and Efficacy: Many pharmaceuticals, especially vaccines, need to be stored at sub-zero temperatures. A deviation from the required conditions can result in denaturation of active ingredients.

2. Preventing Spoilage: Cold chain management prevents the spoilage of sensitive products. This is particularly crucial for medications in regions with fluctuating temperatures or during long-haul transportation.

3. Compliance with Regulations: Stringent global regulations require that cold chain protocols are strictly adhered to for safety and compliance. Proper documentation and monitoring help meet these standards.

4. Combatting Global Warming: With rising global temperatures, maintaining stable temperature conditions during transportation and storage has become more challenging. A resilient cold chain helps mitigate the risks associated with increased climate variability.

Emerging Trends in Cold Chain Pharma

As pharmaceutical discoveries increasingly focus on preventive and pre-emptive therapies, the need for robust cold chain logistics is rising. Here are some of the key trends currently shaping the cold chain industry:

1. Focus on Biologics and Advanced Therapies

The rise of biologics, including monoclonal antibodies, gene therapies, and cell-based treatments, requires stricter temperature management. These therapies are often more sensitive than traditional pharmaceuticals, requiring specialized cold chain logistics. With the growth of personalized medicine, where therapies are tailored to individuals, the demand for specialized cold storage facilities is increasing.

2. Globalization and E-Commerce Impact

With the globalization of the pharmaceutical supply chain and the growth of e-commerce, cold chain logistics have become more complex. There is an increasing need for robust systems to ensure that temperature-sensitive products reach the end-user without compromising quality. This shift is driving investments in advanced cold storage facilities, specialized packaging, and last-mile delivery solutions.

3. Sustainable Cold Chain Solutions

As the industry confronts the environmental impact of cold chain logistics, there’s a push towards more sustainable practices. Companies are investing in eco-friendly refrigerants, solar-powered cold storage facilities, and reusable insulated packaging to reduce carbon footprints.

4. Advanced Packaging Solutions

Innovations in packaging materials and insulation technologies have improved the efficiency of cold chain logistics. Phase Change Materials (PCMs), Vacuum Insulation Panels (VIPs), and temperature-controlled packaging are now commonplace, offering improved temperature stability over longer periods.

Key Technologies Shaping the Future of Cold Chain in Pharm

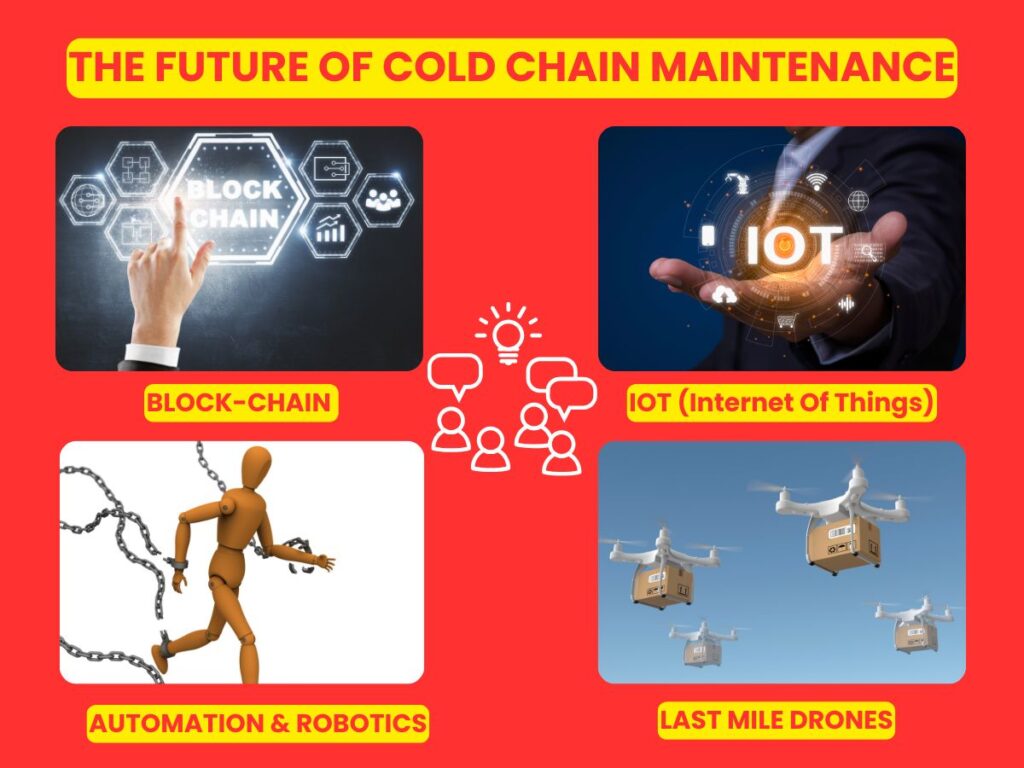

1. Blockchain for Traceability

Blockchain technology is revolutionizing the pharmaceutical supply chain by providing an immutable record of transactions and data. In the context of cold chain, blockchain allows for real-time tracking of temperature and location, offering unparalleled transparency and traceability. If there is a deviation in the temperature at any point during transit, it can be detected immediately, and corrective measures can be taken promptly. Blockchain also helps in preventing counterfeiting, ensuring that only genuine products reach the consumer.

2. IoT and Advanced Temperature Monitoring

The Internet of Things (IoT) is playing a crucial role in cold chain management. IoT sensors are being deployed to monitor temperatures in real-time, enabling pharmaceutical companies to get instant alerts if temperatures move outside acceptable ranges. These smart devices can transmit data continuously, allowing logistics teams to act swiftly in case of any anomalies. In the future, AI-powered predictive analytics will be used to forecast potential risks and optimize routes for better temperature control.

3. Automation and Robotics in Cold Storage

Automation is transforming cold chain logistics. Robotics is increasingly being used in warehouses to handle temperature-sensitive products efficiently. Automated cold storage facilities reduce human error, improve accuracy in inventory management, and speed up the sorting and retrieval of products. This results in a more streamlined and reliable cold chain.

4. Advanced Insulation and Phase Change Materials (PCMs)

The development of advanced insulation materials and PCMs has significantly enhanced cold chain efficiency. PCMs have the ability to absorb, store, and release large amounts of energy, maintaining a consistent temperature range. These materials are now being used in packaging and storage solutions to provide better temperature control, even in extreme conditions.

5. Drones for Last-Mile Delivery

Drones are beginning to play a role in the delivery of temperature-sensitive medicines, especially in remote areas. Equipped with insulated compartments and temperature-monitoring technology, drones can bypass traffic and geographic challenges, delivering essential medicines quickly and safely. This could be especially valuable in disaster-stricken or isolated regions where conventional logistics are disrupted.

Future Outlook: Cold Chain in Pharma

The future of the Cold Chain in Pharma is set to be defined by greater complexity, higher standards, and increased focus on sustainability. With pharmaceutical innovations advancing toward more personalized and biologically complex treatments, the need for stringent cold chain management will continue to grow. Companies that adapt to these demands with robust technology, sustainable solutions, and reliable logistics will lead the way.

As global warming continues to challenge temperature stability, investment in cold chain infrastructure will be critical. Temperature monitoring, AI-driven analytics, and blockchain traceability are not just trends but will become essential tools to ensure the integrity of the pharmaceutical supply chain. In this rapidly evolving landscape, staying ahead of the curve will require not just embracing the latest technologies but also continuously innovating to meet new challenges.

FAQs: Future of Cold Chain in Pharmaceuticals

1. Why is cold chain important for pharmaceuticals?

• Cold chain management is crucial for maintaining the efficacy, potency, and safety of temperature-sensitive medications. Even a slight deviation in temperature can compromise product quality.

2. How does global warming impact cold chain logistics in the pharmaceutical industry?

• Rising global temperatures increase the risk of temperature deviations during transportation and storage, making robust cold chain logistics more important to preserve product integrity.

3. What role does blockchain play in cold chain management?

• Blockchain provides transparency and traceability, allowing for real-time monitoring of temperature and location throughout the supply chain. This reduces the risk of tampering and ensures compliance.

4. What are some innovative packaging solutions used in cold chain logistics?

• Advanced packaging solutions like Phase Change Materials (PCMs) and Vacuum Insulation Panels (VIPs) are used to maintain consistent temperatures and enhance product protection during transit.

5. How are drones changing the landscape of cold chain logistics?

• Drones equipped with insulated storage and temperature monitoring are emerging as a reliable solution for last-mile delivery, especially in remote or challenging locations.

Conclusion

The Cold Chain in Pharma is more than just a logistics solution—it’s the backbone of a safe, effective, and sustainable pharmaceutical industry.

As we move towards more specialized, preventive therapies, and as the climate continues to change, the significance of advanced cold chain logistics will only increase.

Embracing the latest trends and technologies, from blockchain to IoT-driven temperature monitoring, will ensure that life-saving medicines remain potent and effective, regardless of where they need to go. However to a large extent we are have a long way to go as of now.

STAY HEALTHY, STAY BLESSED!